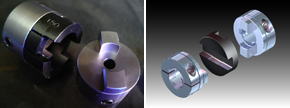

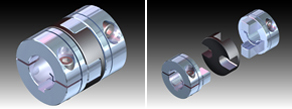

Oldham Flexible Couplings

Advantages:

-

Protects driven component by serving as a mechanical “fuse” – an inexpensive replaceable plastic midsection shears under excess load

-

Protects support bearings by exerting consistently low reactive forces, even under large misalignments

-

Homokinetic transmission – driving and driven shafts rotate at exactly the same speed at all times

-

Zero backlash and high torsional stiffness

-

Electrical insulation

-

Accommodates large radial misalignment in a short length

-

Easy installation in blind or difficult installations when through-bores are used

-

Economically priced compared to other couplings with similar performance characteristics

-

Inexpensive replaceable wear element

-

Low moment of inertia

Disavantages:

- Accommodates a relatively small angular misalignment

Typical Applications:

Printing and copying machines; robotics and servo applications

Variations offered by OEP Couplings:

OI Configuration

A higher torque, higher stiffness variation without the mechanical fuse protective function

Materials

- Materials for midsection: Delrin – for general use; low friction, long wear. High-temperature high-performance thermoplastic; for high-temperature or for more demanding applications.

- Materials for hub: Alloy 360 brass, alloy 2011 aluminum, and alloy 303 stainless steel

- Shaft attachment options: Set screw without keyway, set screw with keyway, clamping without keyway, clamping with keyway

- Torque-limiting option – as detailed in this Case Study, we offer midsections that will break cleanly at a torque specified by the customer, as a replacement for other conventional, more costly torque-limiting devices

Why OEP?

Advantages of OEP Couplings’ Oldham configurations over those of other manufacturers:

- Higher torsional stiffness, longer service life, and more consistent performance from one coupling to another due to tighter machining tolerances and better surface finishes

- Higher static break torque and higher peak torque due to small but critical geometrical features, details of fabrication techniques, and the use of advanced materials and processes

- Higher RPM rating because of dynamic balance inherent in every coupling