Rigid Couplings

Advantages:

- Torque limited only by clamping force between coupling and shaft

- Simple, economical

- Low moment of inertia

- Driving and driven shafts maintain relative angular position

Disavantages:

- Metallic versions can accommodate virtually no shaft misalignment, and nonmetallic versions only trivial amounts of misalignment – and some shaft misalignment is always present between any two shafts. Even after precision alignment, thermal expansion during operation will lead to some radial misalignment if both shafts are fully radially constrained.

Typical Applications:

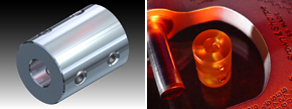

Applications requiring hermetically sealed rotary feed-through, including specialized pumps moving caustic or hazardous material; semiconductor fabrication equipment; laboratory apparatus.

Variations offered by OEP Couplings:

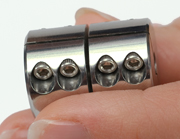

Type RS: Set screw.

Type RC: One-piece clamping

Type RT: Three-piece clamping.

Materials

- Materials: Nickel-plated 1018 steel, alloy 7075 aluminum, alloy 303 stainless steel, Ultem (offering electrical insulation)

-

Shaft attachment options: Set screw without keyway, set screw with keyway, clamping without keyway, clamping with keyway

Why OEP?

Advantages of OEP’s Rigid Couplings over those of other manufacturers:

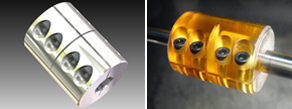

- All rigid couplings are precision-machined from bar, offering better strength, fit, and overall quality than cast or powdered metal couplings.

- Machined to tighter tolerances than those of other manufacturers, improving fit between shaft and bore, dynamic balance, and so on.

- Full range of sizes, materials, and shaft attachment options available