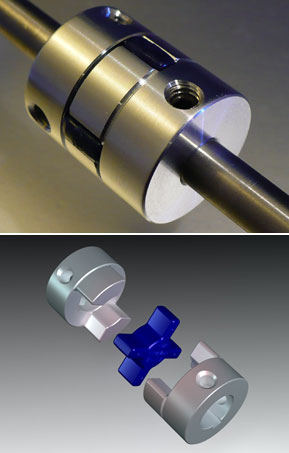

Jaw Couplings

Advantages:

- High torque capabilities

- Different material choices for the spider allow the user to choose torsional stiffness

- Somewhat “fail-safe”, in the sense that the driving hub will continue to turn the driven hub after failure of the spider

- Easy installation in blind or difficult installations – all jaw couplings have through bores

- Dampens variations or spikes in torque, usually caused by the driving element, protecting the support bearings and the driven component, and reducing vibration

- Wear element can be reversed before being replaced, doubling life

- Rugged, can function well in harsh environments

- Replaceable, inexpensive wear element

Disavantages:

- Relatively high reactive forces exerted on support bearings, proportional to misalignment

- Even preloaded, so-called “zero backlash” jaw couplings have considerable wind-up, which is essentially the same as backlash, and disqualifies jaw couplings from servo applications

-

Accommodates relatively small misalignments, considering large size of couplings

Typical Applications:

Pumps, particularly gear, lobe, vane, and reciprocating pumps; also applications involving piston motors, or any system with high torque and vibration, where relative angular location of the two shafts need not remain constant. High-temp spider option good for down-hole directional drilling applications.

Materials

- Materials for midsection: Urethane: Good all-around performance; NBR: More torsional dampening; high-temperature rubber: For high-temperature applications or applications exposed to chemicals incompatible with other elastomers.

- Materials for hub: Alloy 7075 aluminum, alloy 303 stainless steel, nickel plated alloy 1018 steel

- Shaft attachment options: Set screw without keyway, set screw with keyway, clamping without keyway, clamping with keyway

Why OEP?

Advantages of OEP’s Jaw Couplings, over jaw couplings from other manufacturers:

- Miniature sizes available

- Spiders available in various materials and hardness; hubs available in various materials

- All hubs very precisely machined from bar: No cheap castings or powdered metal parts, resulting in better overall and more consistent performance

- Unique geometry of spider, and low coefficient of friction between spider and hubs, minimizes reactive forces, and reduces heating of spider during operation